Working principle:

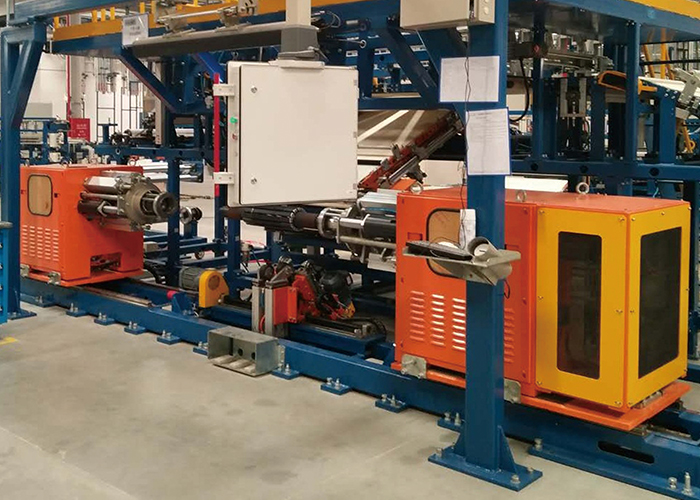

1、Under the drive of the servo motor, the main shaft of the host sequentially apply the rubber sheet and ply onto the building drum. According to the user's process requirements, it can achieve precise positioning of the joint angles of each rubber sheet and ply, the two sides of the building drum can achieve the turn-up action of the steel wire ring, with the back stitcher device, it can quickly and efficiently complete the production of air spring tire embryo.

2、The rubber sheet and servicer of ply layer at the back can accurately cut and automatically feed the film and curtain by the user's setting requirements, in order to meet the building action of the building drum and complete the task of building the embryo.

Equipment features: This air spring building machine has the advantages of high automation, precise positioning, and high production efficiency, greatly reducing the labor intensity of operators and improving yield efficiency.

Convenient formula management: The operation interface adopts touch screen management, which facilitates employees to manage different production formulas and enables quick switching.

Information management: It can be connected to production management software such as ERP and SAP to achieve automatic statistics of production data.

Safety management: The operating parts of the equipment are equipped with safety devices, which can be immediately shut down in case of emergency to protect the safety of personnel and equipment.

Other usage requirements can be added according to user needs to fully meet customer needs.

| The height range of practical air springs | 370-600mm |

| Diameter range of air spring | 106-205mm |

| Use curtain width range | 490-680mm |

| Rubber sheet width range | 280-700mm |

| The diameter range for roll winding the ply rubber sheet | 180-350mm |